VETEC Anlagenbau GmbH

Adresse

VETEC Anlagenbau GmbH

Karoline-Herschel-Straße 2

27283 Verden (Aller)

Germany

Telefon+49 4231 7777

Fax+49 4231 777868

Entdecken Sie mehr von uns

Folgen Sie uns auf

Über uns

VETEC ANLAGENBAU offers customized system solutions for the thermal treatment of foodstuffs such as meat and sausage goods, fish, bread, cheese, vegetarian and vegan products, pet food and many more. Convince yourself of our comprehensive product range of smoking installations, intensive cooling and cooking installations, climatic ripening installations, defrosting installations as well as semi-continuous and continuous installation systems.

In this business field, we have built up extensive expertise over decades and established ourselves as market and technology leaders with our innovative products. We rely on the dialog with our customers in our fully equipped customer seminar and development center, which provides our customers with a broad installation portfolio for tests and demonstrations on more than 500m².

In addition to our established diverse range of installations and smoke generators, VETEC ANLAGENBAU is continuously developing new energy-efficient and resource-saving installation systems to perfect your thermal processes. Through a high level of quality, safety and profitability- coupled with a comprehensive range of services - we meet the high demands of our international, industrial clientele. These include many well-known manufacturers of meat and sausage products in Germany and abroad as well as other internationally active food producers. With its approx. 160 employees at the Verden/Aller site, VETEC ANLAGENBAU focuses on individual, customized system solutions based on state-of-the-art technology.

This high demand on man and machine, coupled with many years of experience and new ways of thinking, generates a corporate culture at VETEC ANLAGENBAU that ensures continuous growth and innovation. We accompany you competently from the first consultation to the technological start-up and develop in close cooperation individual solutions according to your requirements for your premium product.

VETEC ANLAGENBAU - WE BUILD YOUR SOLUTION

Unsere Produktgruppen

- Baking, roasting and frying equipment

- Ovens, baking chambers

- Thawing systems / defrosting equipment

- Cooking units, cooking chambers

- Cooking units, continuous

- Hot smoking units

- Hot smoking units, continuous

- Climatic maturing systems, climatic post-maturing systems, air-conditioned storage rooms

- Smoke generators

- Other cooking and smoking systems

- Process control

- Process control engineering

- Process automation

Downloads

Dokumente

Keywords

- Cooking Installation

- Smoke House

- Kochanlage

- Maturing

- Heissrauchanlage

Unsere Produkte

CLIMAMAT DEFROST

The VETEC CLIMAMAT DEFROST thaws out deep-frozen food exceptionally gently and with a focus on quality. Entire blocks or individual products: Thawing with air at a very high relative humidity ensures an even and hygienic process, regardless of whether open or packed products are involved. The process is reliable and stable and the products maintain their delicate structure without dry edges and with consistent colouring. Temperature sensitive products can be thawed exceptionally gently.

In order to guarantee a product-friendly and economical process, controlled process management is necessary. By means of interval and temperature automation depending on the surface temperature the CLIMAMAT DEFROST guarantees an optimal thawing result. Sensors on the product record core and surface temperature and are used for a control system optimally adapted to your product. In this way, partial overheating is avoided while the defrosting process is accelerated. Due to the high air humidity during the process, weight losses can also be kept extremely low. The risk of cross-contamination with germs via the air is eliminated and humidification with steam instead of water avoids additional germ entry. In addition, the CLIMAMAT DEFROST can also be used as a cold store.

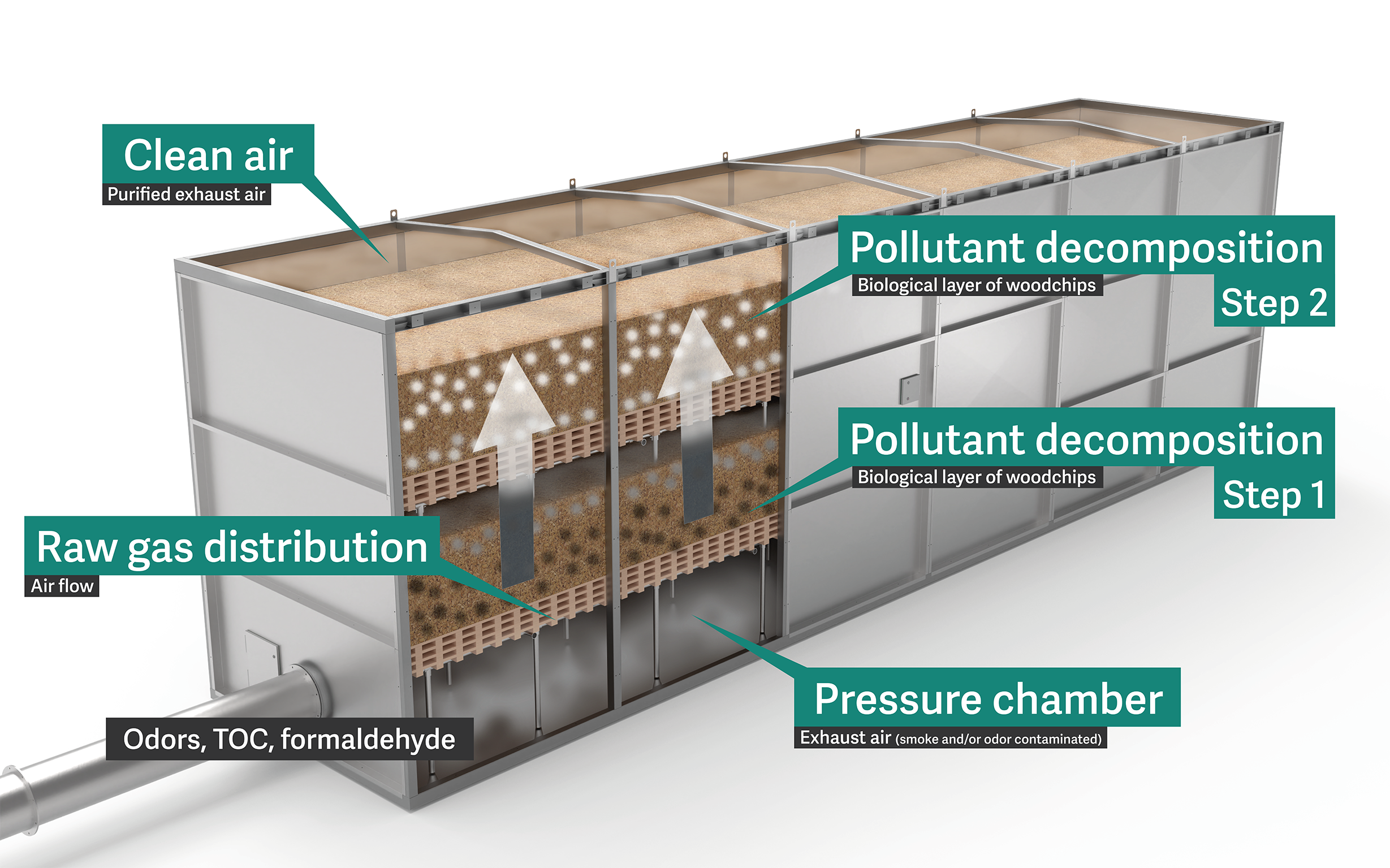

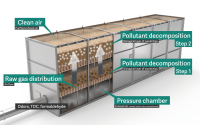

ECO AIRCLEAN F - Exhaust air treatment

In the exhaust gas treatment of Hot Smoke and Cold Smoke Installations, the biofilter concept has proven itself as a method for cleaning exhaust air containing carbon and odors.

With the new ECO AIRCLEAN F, VETEC Anlagenbau has further developed the technology so that all odors and flue gases produced during the thermal processing of meat and sausage, fish, cheese and pet food can be treated efficiently and cost-effectively in multiple stages.

CLIMAMAT HIGH CUBE

The revolutionary CLIMAMAT HIGH CUBE multiplies your production volume on a constant production area through extra high racks (up to 7m / 23 ft.). The alternating treatment of the upper and lower chamber area paired with our air change flap or double vents is the most efficient way for maturing, smoking and storing air-dried meat and salami products on extra high racks. Full automation of loading and unloading by AGV / LGV is considered here.

Your products are treated particularly gently and reliably. Drying and smoking takes place automatically alternating between the lower and upper chamber halves, as well as in the chamber from left to right and vice versa. Due to the high air output and the perfectly optimized air flow, you obtain absolute uniformity even with very large production capacities, coupled with extremely short batch times.This principle allows processes to be controlled reliably and with reproducible results. Engineering and technology are based on our proven climate control systems of the CLIMAMAT - series.

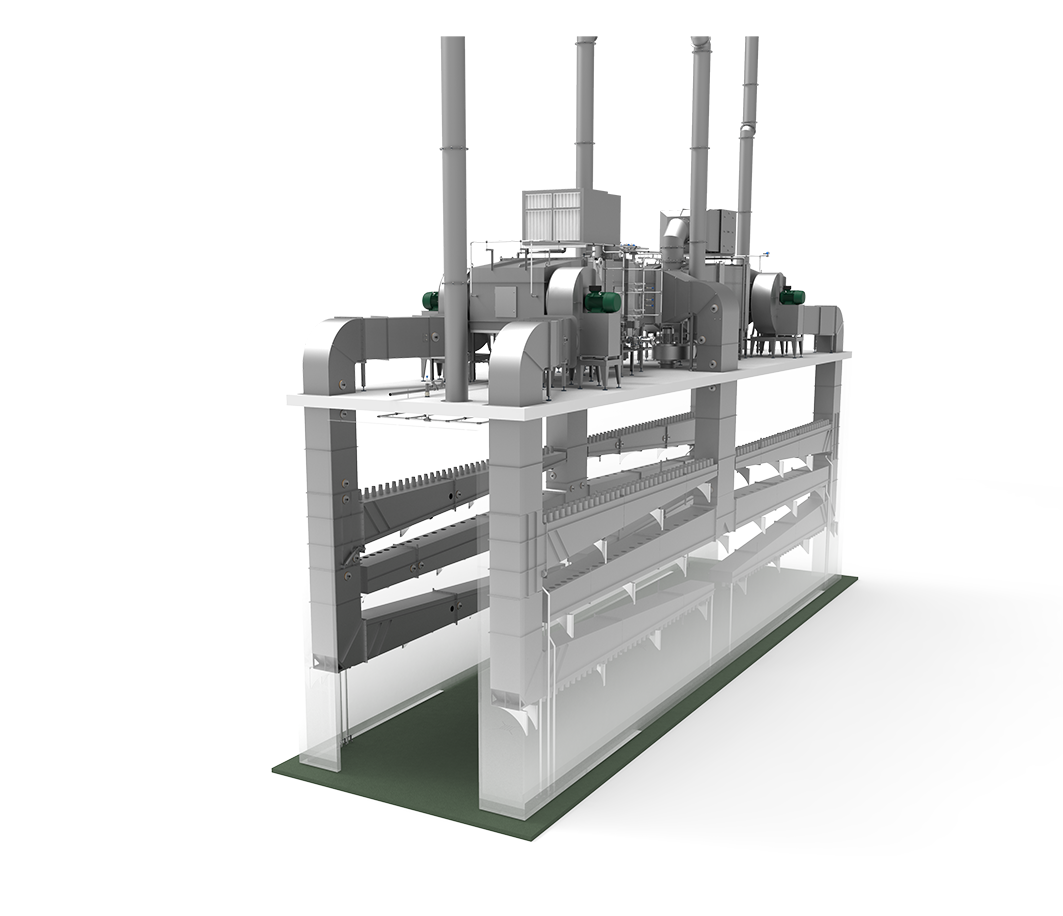

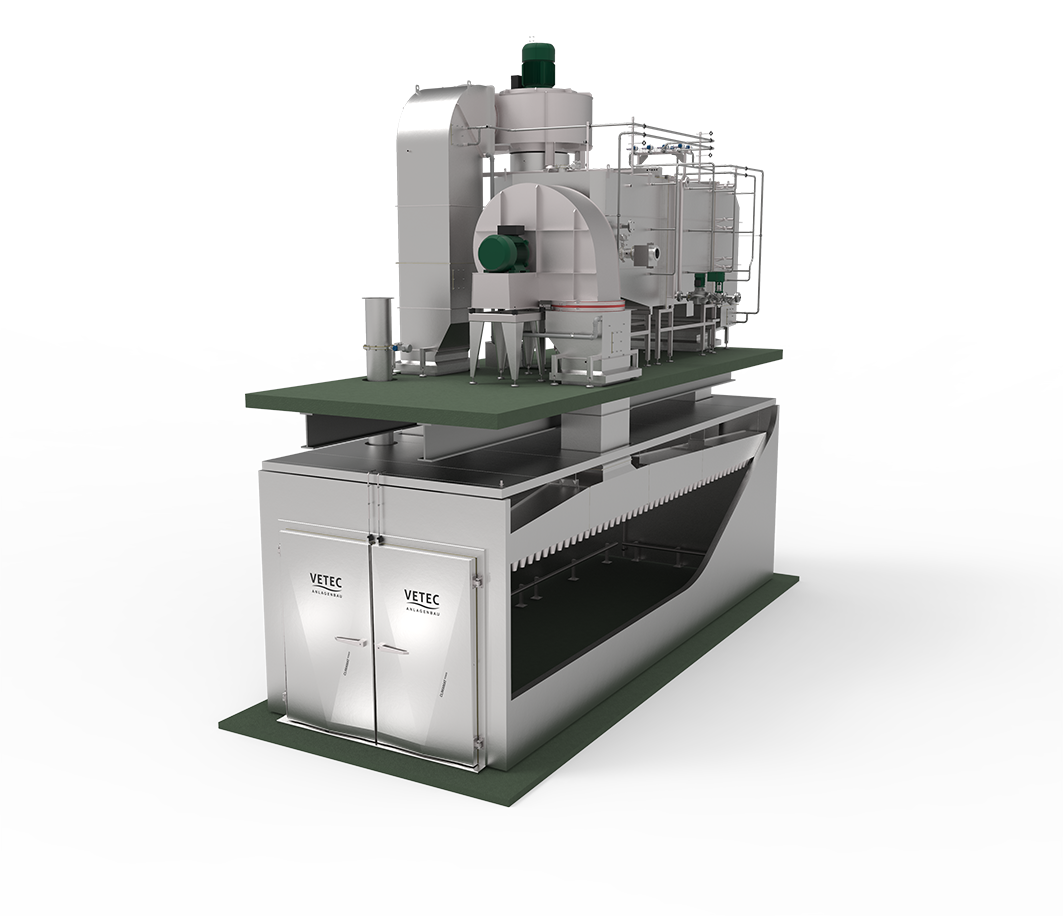

AEROMAT COMPOUND

The AEROMAT COMPOUND from VETEC ANLAGENBAU combines the tried and tested technology of a hot-smoking and cooking installation with an intensive cooling section. In the first step, your product undergoes the following processes: Reddening, drying, warm and hot-smoking, boiling, cooking and hot-air cooking in the hot-smoking and cooking section. The food is then cooled down with shower water and air in the intensive cooling section. The semi-continuous handling system makes the AEROMAT COMPOUND a flexible solution for your meat product production.

The AEROMAT COMPOUND is the key to rational design of your production processes. Automatic transport of your products from hot to cold treatment makes a decisive contribution to consistent product quality and minimal weight losses. At the same time, interventions in the process are reduced as transport into the cooling section without outside intervention allows hygienic separation between the raw and production sections. There is no need for staff to enter hot chambers, which noticeably improves working conditions.All you have to do is position your trolleys at the first position in the hot-smoking and cooking section. The electric handling device moves each trolley to the correct position. After loading the installation, start your program.As soon as the heat treatment is complete, the AEROMAT COMPOUND opens the automatic doors to the intensive cooling section and transports your products into it. There, they are immediately cooled to packaging temperature and dried with shower water and cold air. At the end of the program, the handling system transfers the trolleys to you individually for subsequent processes such as packing. Because of the flexible transport in both directions, it is possible to use only the hot-smoking or intensive cooling section if production changeovers require this.The handling device is totally reliable even with very high trolley weights.

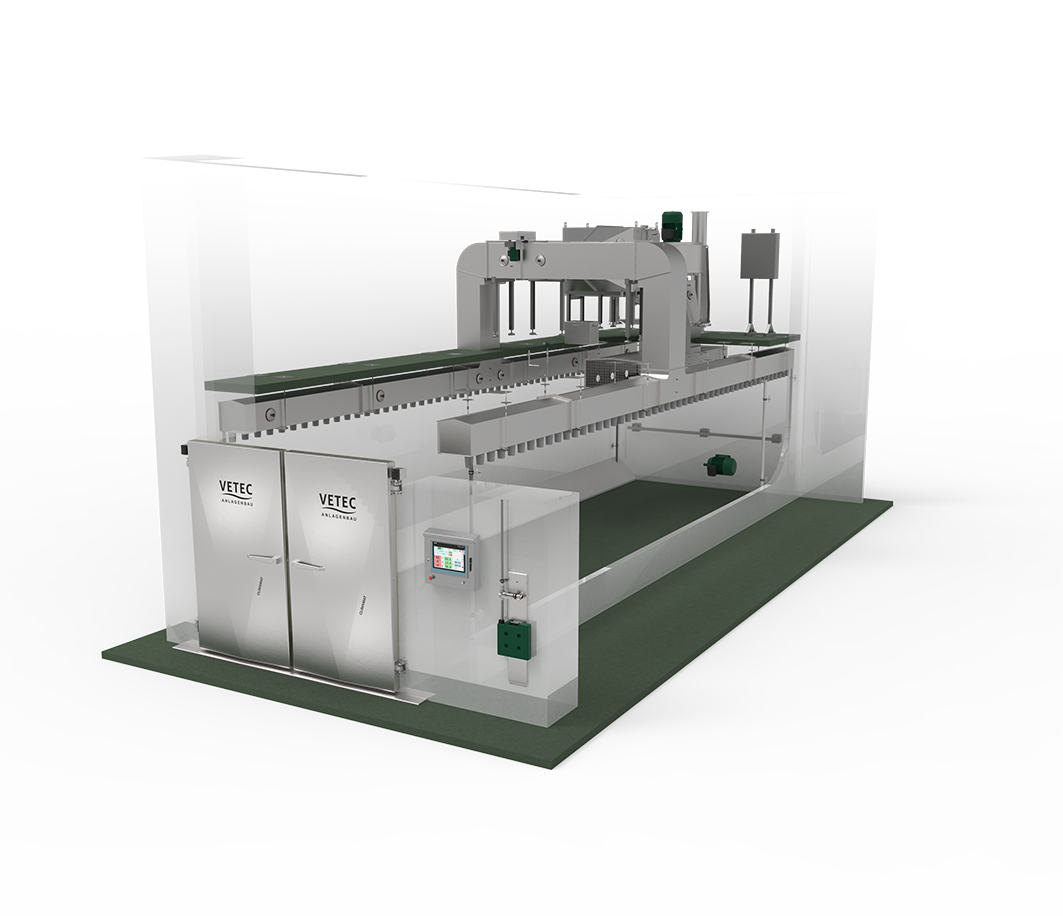

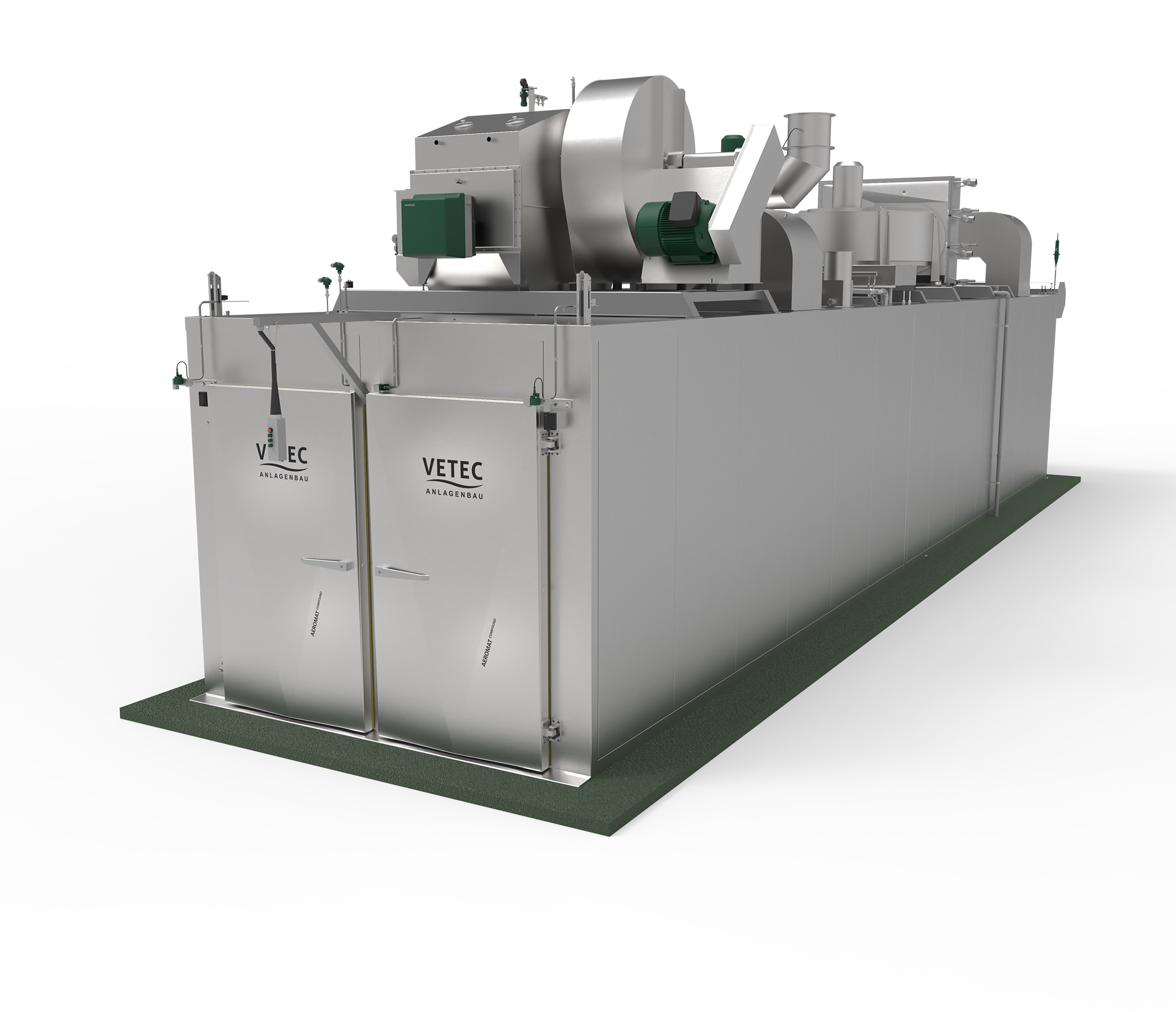

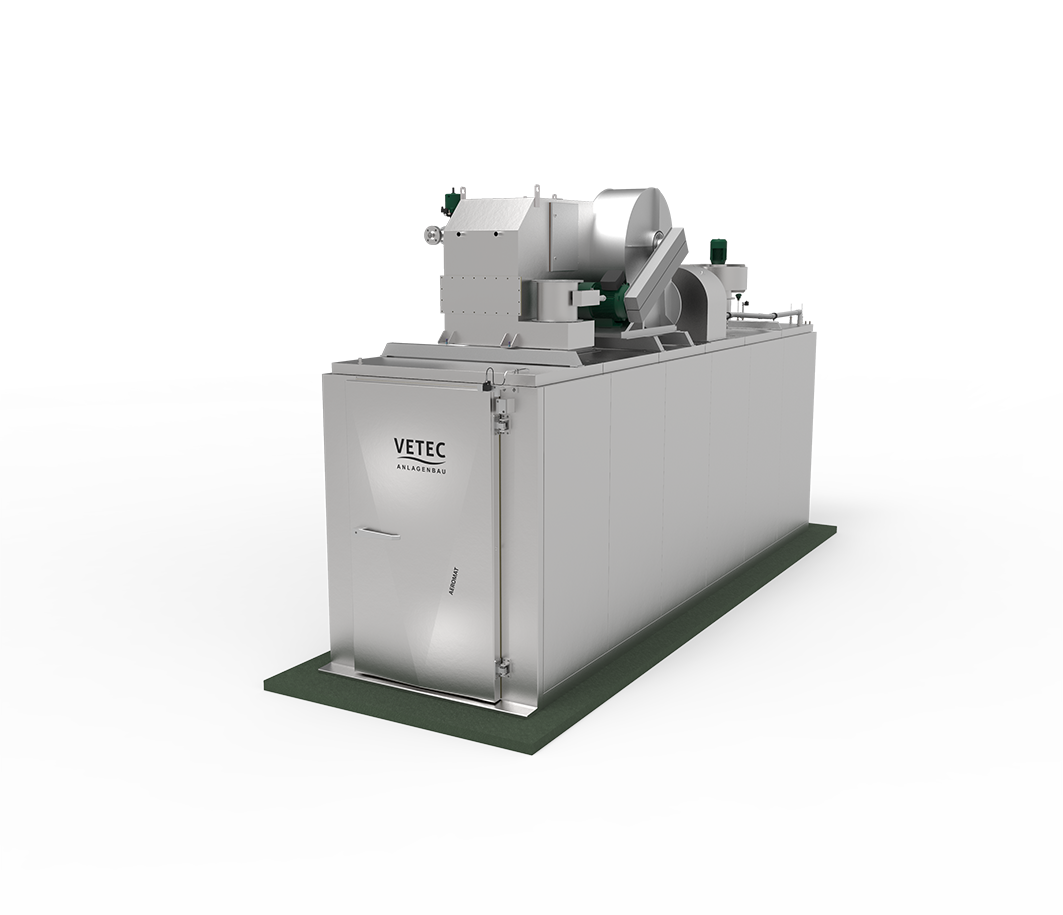

AEROMAT

The VETEC Allrounder AEROMAT is the perfect solution for different thermal treatments of your premium product. The combined installation offers standard functions like reddening, drying, smoking and cooking, next to optional functions such as cold-smoking, baking or cooling. No matter how you want to process your product, the AEROMAT by VETEC delivers optimal and reproducible outcome.

In order to produce a top-quality product of consistent quality in the shortest possible time, the same climatic and flow conditions must prevail throughout the whole chamber. The central air condition unit conditions the air and enables a consistent climate throughout the whole chamber and avoids hot or cold spots.The radial fan circulates the whole chamber volume several times a minute at intervals adapted to suit the process, guaranteeing that a perfect product with consistent quality always results. In addition, the tried and tested air change flap system ensures dynamic circulation of air around the product, achieving greater consistency.